Our Technologies

We combine cutting-edge applications with versatile designs that accommodate a wide range of requirements.

Our Technologies

We combine cutting-edge applications with versatile designs that accommodate a wide range of requirements.

Bonding

Bonded Zippers

Bonded zippers offer improved performance when compared with bulky sewn-on versions. Without the need for seams, the zippers can be attached in various ways, allowing for endless design opportunities.

Bonded Pockets

Bonded pockets eliminate the friction created by internal pocket seams. Wearers will benefit from the comfortable feel, while the garment will have a smooth and seamless look.

Seam Tape Joining

This technology offers improved durability and a clean, seamless finish to garments. When layered over traditional sewn seams, a smoother aesthetic is achieved, while two or three layers of taping give the garment waterproof capabilities, even over curved seams. When combined with specialised Flomak tape, items will be lighter than those made with sewn seams.

Ultrasonic Reinforced Taping

This technology replaces traditional seams, improving strength and durability at the fabric join. This taping is used on waterproof garments and also drastically improves water-resistance on other garment types.

Overlap Joining

This technology allows for garment construction without the need for seams. Clothing will have a smoother, minimalistic aesthetic and wearers will benefit from a comfortable, frictionless feel.

Bonded Waistbands

Bonded waistbands offer a firm, comfortable hold with decreased shifting and twisting as the wearer moves. Waistbands are crafted with Flomak’s special tapes and cutting-edge application methods, allowing them to recover their shape easily and giving them an uncomplicated aesthetic.

Foldever Hems

These folded hems give garments minimalistic appeal. Most often used on performance garments, the smooth finish offers a clean look.

Edge Binding

Edge binding minimises garment-to-skin friction for improved comfort. Bindings can be applied to hems and other garment edges such as pocket openings and necklines.

Garment Technology

Padded Jackets

Flomak is able to create multiple padded jacket styles, always of the highest quality and from sustainable materials. The fabrics we use offer impressive warmth and heat retention without feeling bulky, as well as providing superior lightness when compared to wool or leather.

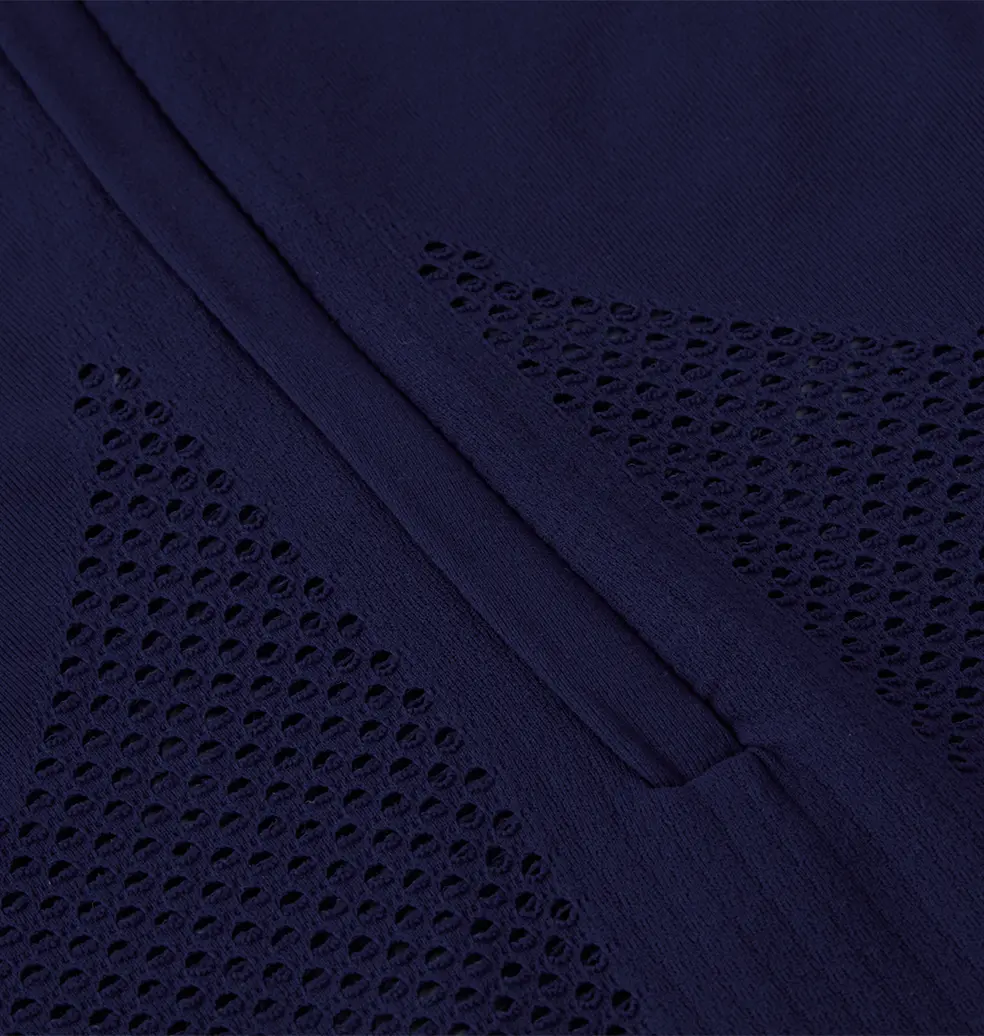

Hybrid Seamless Technology

With this technology, Flomak is able to attach garment panels that are developed without the use of traditional seams. Both knitwear and woven items are made more comfortable by this seamless construction.

Pleats

Pleats can contribute to a garment’s silhouette, as well as to the overall aesthetic statement. Flomak can create pleats of all kinds – lightweight and airy, solid and structured or complex with intricate detailing.

Garment Dyeing

The garment dyeing process changes the garment colour after it has been fully constructed. The benefits include a fashionably worn or subtly faded look and a soft feel.

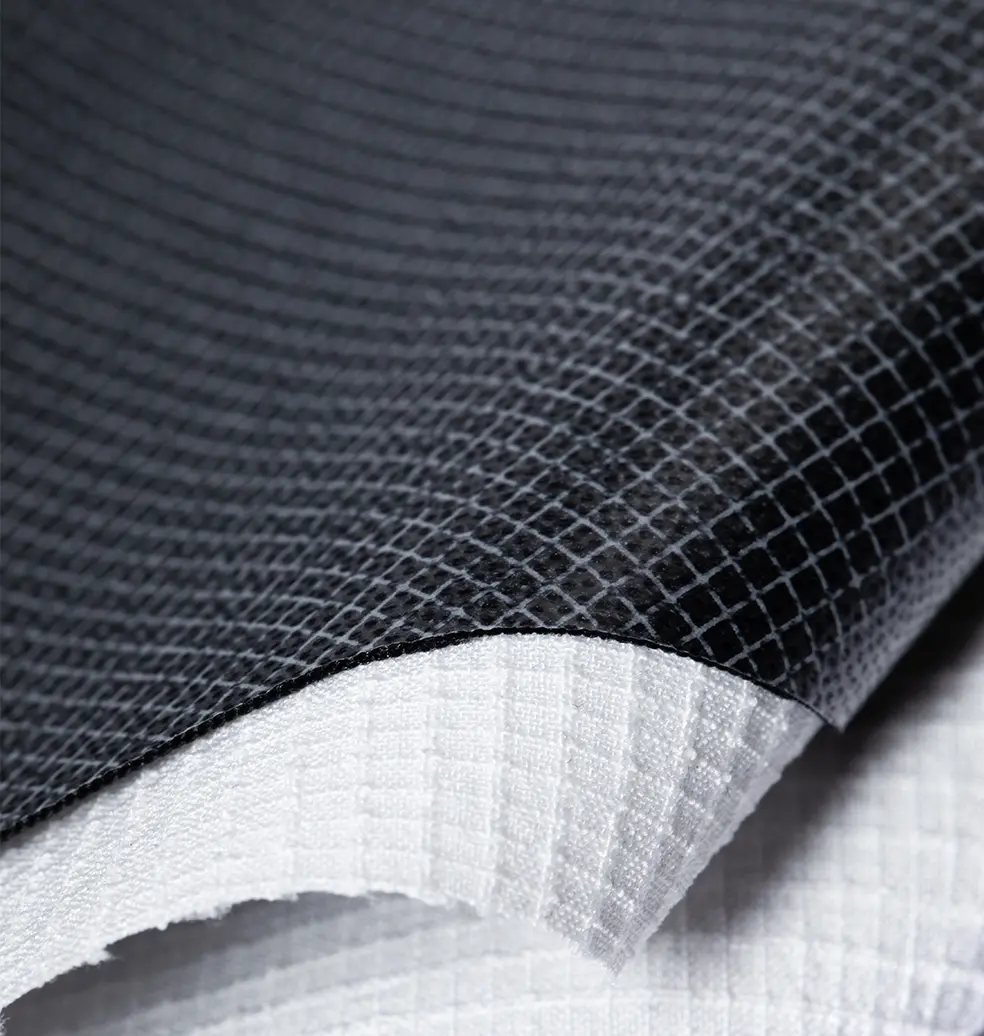

2 and 3 Layer Breathable Jackets

Our special membranes ensure that garments maintain breathability, keeping hot air and moisture out for a comfortable, ventilated feel. Fabric strength and recovery are not compromised by lightness and flexibility.

Thermal Moulding

Moulding technology is ideal for the creation of 3D garment shapes, such as bra cups. A comfortable feel is maintained thanks to the absence of seams, while support and freedom of movement are also provided.

Technical Trims

Laser Cutting

Laser cutting technology allows for the creation of an endless variety of shapes and patterns. In addition to meticulous cut-out details, mesh panels can be ‘carved’ onto garments to improve breathability on activewear.

Ultrasonic Pattern Cutting

A fast and efficient method of adding patterned finishes to materials, with minimal damage to the fabric's structure. Ultra-high frequency ultrasonic sound waves are used to achieve the desired aesthetic. In addition, a pleasant soft touch effect is created.

Flatlock Stitching

This method of joining fabric pieces together does not require for the pieces to overlap, resulting in a smoother seam. The stitching between seams is visible on the outer garment and adds to the item’s overall aesthetic.

Reflective Embellishments

These high-visibility safety details ensure that the wearer can be seen at night or in low light. The embellishments are available in stretch and non-stretch options to match the base garment for efficient application.

Embroidery

Design elements can be applied to the garment using different embroidery techniques to add visual depth.

Anti-Slip

These discreet details prevent the slipping and shifting of garments, keeping them in the desired position for safety, performance and aesthetic reasons. Cycling pants, blouses, bras and other underwear all benefit from these functional trims.

3D Embossing

3D design details can be moulded directly onto the fabric of garments, without the use of stitches. This technology can be used to add branding elements or other features, while bringing visual depth to the garment.

Prints & Heat Presses

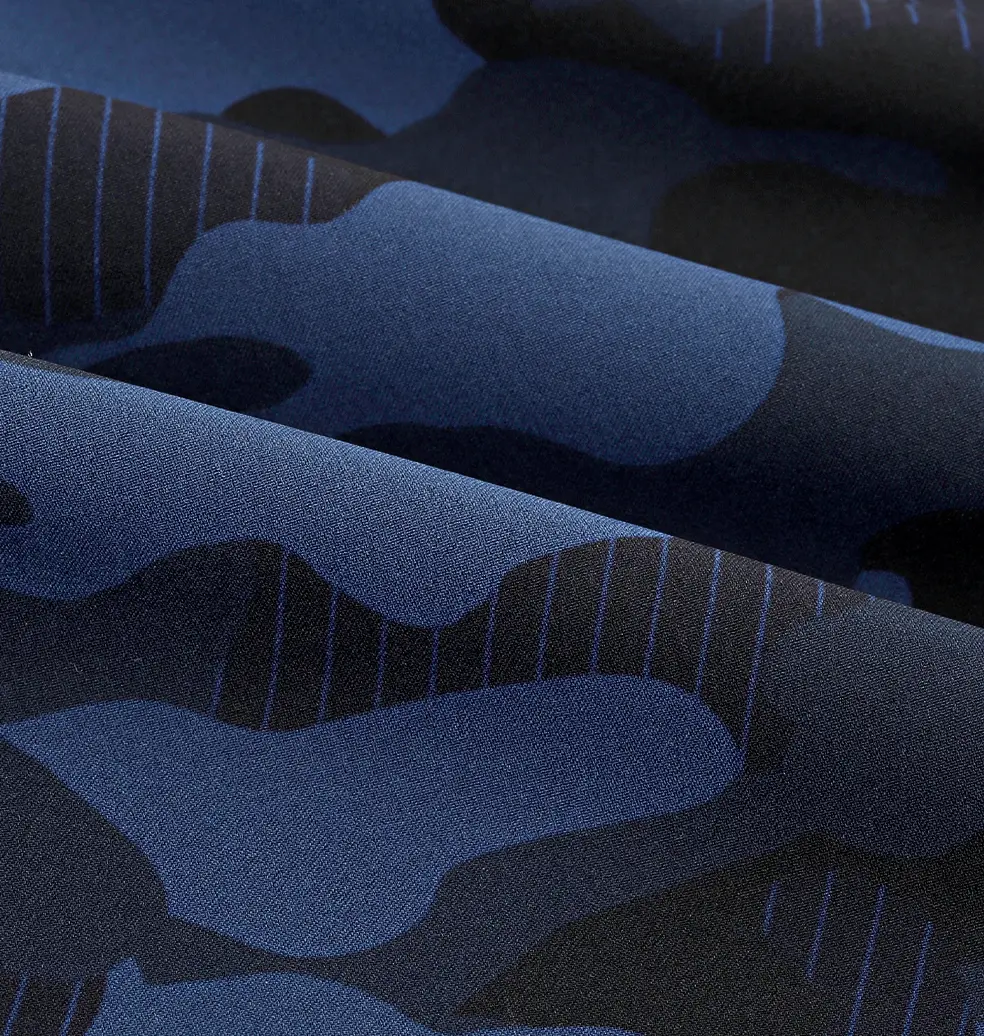

Sublimation

During the sublimation process the desired print pattern is rendered on paper before being heat transferred onto the fabric. The printing possibilities are endless – text, areas of colour and all types of images including photographs can be recreated on fabric.

Heat Transfer

Flomak offers heat transfers of woven and embroidered patches. This method provides superior resolution when compared with screen prints and we can attach all types of multi-colour flat PU heat transfers including those with reflective and silicone finishes. 3D patches are also accommodated.

Digital Printing

We use acid inks applied directly on to polyamide fabrics, this results in rub fastness and a more durable finish, even after washing.

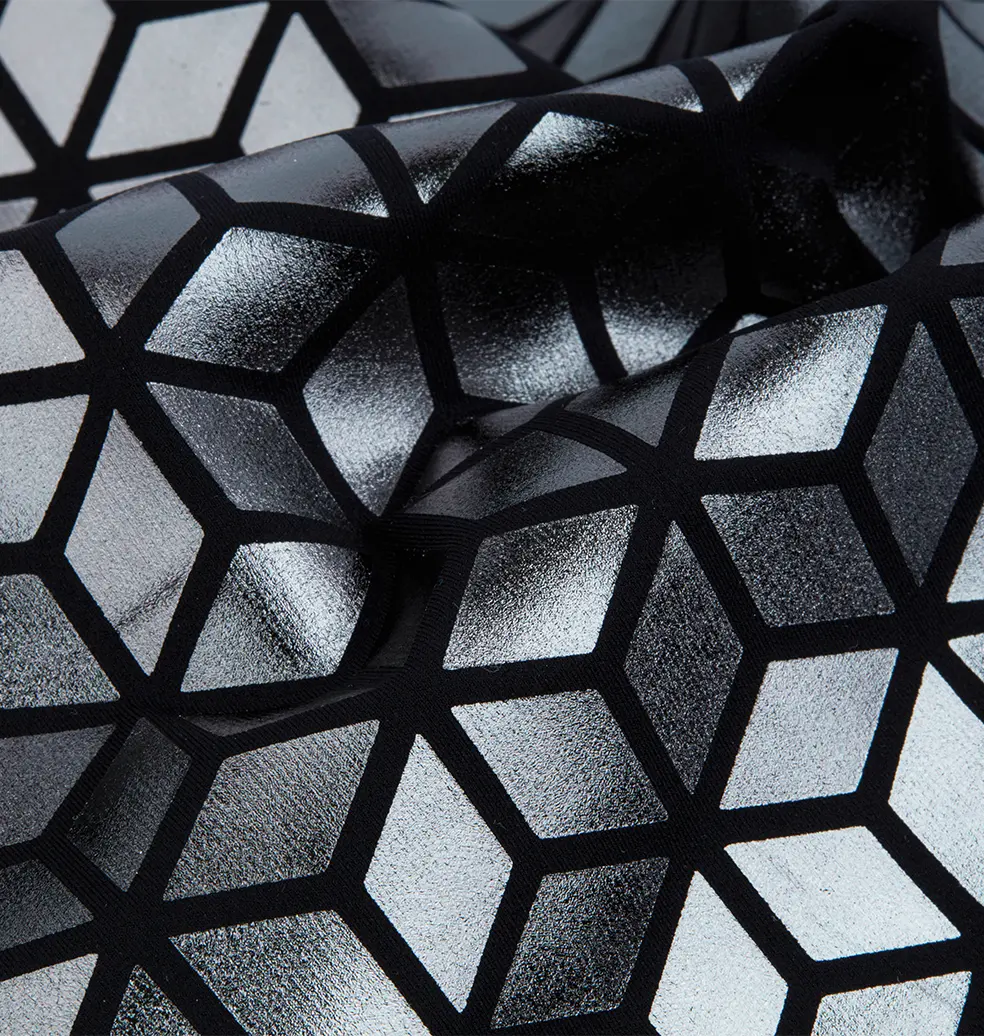

Foil Printing

Also known as foil stamping, foil printing uses heat, pressure and foil paper to create a matte or a metallic print. The foil paper is acquired in pieces or in rolls and can be applied to various fabric types.

Pad Printing

Also known as tampo printing, pad printing is a specialised process that involves the transfer of a 2D print image from a laser-engraved printing plate to a silicon pad. The image is then transferred to the fabric or garment. It is a more economical process and has longer lasting effects than conventional heat transfer printing.

Rotary & Flat Screen Printing

Rotary printing involves the pressing of print ink through a mesh cylindrical screen onto the fabric, with a separate screen engraved for the application of each colour. This process allows us to use reactive, acid and pigment dyes and yields high-quality results with multi-colour designs. Flat screen printing is similar to rotary printing, however the process is more manual. Similar levels of colour variation and depth can be achieved. Unlike rotary printing, it is possible to print on a specific part of a garment only.

Cracking Print

Flomak uses specialised print chemicals to create a cracked appearance on prints. This distinctive effect adds a fashion-forward look to garments.

3D Modelling

This time-saving and eco-friendly approach replaces physical sample garments with virtual ones. 3D garments are built on digital models to your brand’s size specifications, allowing any modifications to be made quicker and reducing the number of prototypes required. Overall, a better fit is achieved and waste is greatly reduced.

3D Modelling

This time-saving and eco-friendly approach replaces physical sample garments with virtual ones. 3D garments are built on digital models to your brand’s size specifications, allowing any modifications to be made quicker and reducing the number of prototypes required. Overall, a better fit is achieved and waste is greatly reduced.

With the help of 3D technology, we dramatically reduce the number of physical prototypes, helping reduce waste, ensuring a better fit and accelerating time-to-market.

Fabric Treatments

Quick-Dry

Quick-dry treatments make sure the wearer stays dry by making moisture evaporate from fabrics quickly. These sweat-wicking capabilities offer a cool, ventilated feel.

Anti-bacterial

This treatment keeps fabrics fresher for longer. The properties of silver ions and cellulosic fibres prevent the production of odour-causing bacteria.

Antiviral

This highly effective treatment utilises active ingredients that have an antimicrobial effect on fabrics. It is used in the fashion industry as well as in the healthcare sector, where it can be modified to work on viruses such as SARS-Cov-2 (Covid-19) and Influenza A.

Water-repellent

This treatment provides a degree of water-resistance to garments, without making the item stiff and uncomfortable. The surface finish is effective at keeping the wearer dry while remaining breathable to some extent. There are three types of water-repellent finishes: wax-based, silicone-based and fluorocarbon-based.

Hydrophilic

Hydrophilic treatments attract water in order to expel it. This finish offers fabrics the moisture-wicking ability that is most often seen on performance wear.

Cooling

Using thermoregulation technology, fabrics are able to respond to changes in body temperature. The fabric will cool the wearer when hot and sweaty, and the function is deactivated when not needed. It’s ideal for items worn directly against the skin, like sportswear and underwear.

UV-proof

This treatment is applied to garments used for outdoor activities such as running, hiking and cycling, particularly if worn in hot environments. Dangerous UV rays are repelled for safer wear in direct sunlight. UV-proofing is often combined with cooling technology.

Anti-pilling

With this treatment, friction is reduced and shorter fibres are held together for less pilling. Open-end yarn fabrics will especially benefit from this finish.

Anti-static

Electrostatic charge is produced during production as well as during the wear of garments, particularly those made with knits and synthetic fibres. The uncomfortable feel of static is removed by this treatment.

Anti-mosquito

Items with this treatment are great for outdoor performance wear, and for everyday apparel. Fabrics are given a protective finish that shields against mosquitos, and the diseases that they may carry.

Flame Retardant

Increased safety is offered by items treated with chemicals that suppress the combustion process to avoid fires. Different types of treatments are available to suit a variety of safety standards and requirements.

Anti-wrinkle

This treatment helps to keep clothing crisp and crease-free. Fabrics that are naturally resistant to wrinkling include synthetics like polyester, nylon, acrylic and olefin.

Softening

Softening treatments add a silky touch, a flexible feel or a glossy effect to fabrics. In addition, garments will recover quicker after movement or wear.

Deodorising

This finish gives fabrics the ability to emit a pleasant perfume smell when rubbed. When the garment is not in use and no abrasion occurs, the aromatic atoms will not be broken down, therefore there will be no scent. However, it is also possible to apply this treatment so that it releases perfume continuously whether abrasion occurs or not.